The customer is an international manufacturer of industrial polymer and plastic products, with operations spanning over a dozen manufacturing facilities in Europe and Asia.

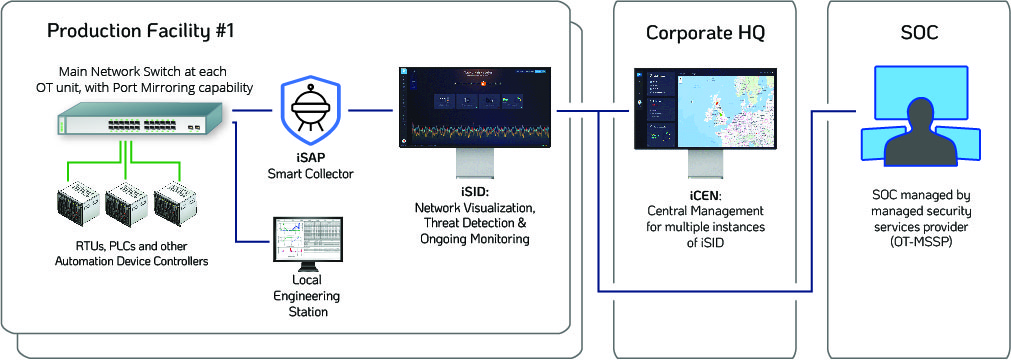

The customer had already deployed Radiflow’s iSID industrial threat detection and management platform (in conjunction with iSAP smart collectors at operational units) at a pilot site in Europe.

The pilot, which followed a thorough selection process, was driven by a cyberattack on the company’s facility. Upon review of the outcomes of the pilot installation the customer decided to extend it to four additional factories in Europe.

The objectives of project included:

Deployment of the project’s various components faced two challenges:

Lack of remote access to switches, which required physically accessing each network cabinet across the production array at all sites

Travel and work limitations due to Covid-19, which meant that physical installations were performed by local personnel and remotely configured by the Radiflow team

Radiflow’s solution consisted of a central, virtual (VM ware) instance of iSID at each site for analysis of all data traffic network-wide.

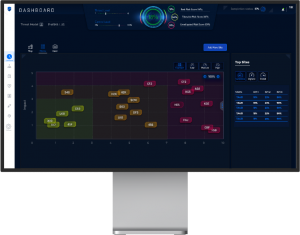

Upon self-learning each facility’s network and assets, iSID would provide full network visibility (in the form offlexible network maps). All instances of iSID would be accessible using a single iCEN management dashboard.

For efficient data transfer to iSID, iSAP smart collectors were to be installed at each operational unit at both locations.

iSAP’s data filtering and compression algorithm (up to 90% reduction in packet volume with no effect on operational data) prevents LAN overload and would eliminate the need to add bandwidth to accommodate to further expansion.

Deployment

As mentioned, Covid-related travel and labor restrictions necessitated that all physical installations of Radiflow products would be performed by the customer’s personnel at each site.

In the end, deployment went extremely smoothly, attesting to the customer’s staff’s professionalism as well as to Radiflow solutions’ ease of installation, both physical and virtual.

Once installed, and once all iSAP smart collectors were connected to mirrored ports (to ensure nonintrusive monitoring), the first step was self-learning the network and constructing a digital image of the industrial network including all assets properties and vulnerabilities, logical asset groupings, ports and communication protocols.

The digital image is used for network visualization, down-drillable to all asset attributes, as well for anomaly detection, serving as a “clean” baseline-activity model for “beyond-the-horizon” threat detection.

The project also calls for monthly network analyses and issuing of various security reports for different stakeholders in the organization.

The deployment of Radiflow’s solutions at all of European sites has been concluded to the full satisfaction of the customer, who has announced plans for additional expansion to facilities in Asia.

CIARA is able to optimize IT-OT security expenditure by assessing the customers’ overall exposure to cyber-risk (accounting for the actual impact of an attack on different business units) and prioritising threat mitigation measures by their ability to reduce risk

One Weak Password, Full Process Control: Inside Norway’s 2025 Dam Cyberattack

Project Management in OT/ICS Projects with IEC 62443 and MITRE ATT&CK using Radiflow

Rogue Communication Modules in Solar Inverters: Radiflow Threat Analysis